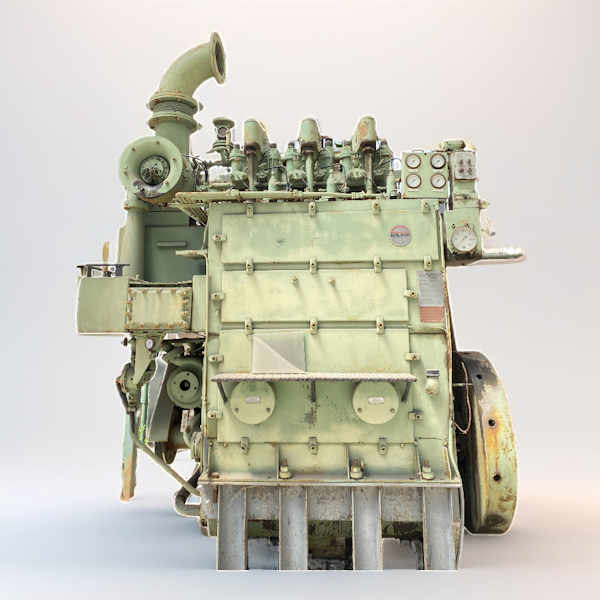

The BOLNES DNL engine is a naval engine produced by the Dutch BOLNES Motoren Fabriek in 1973.

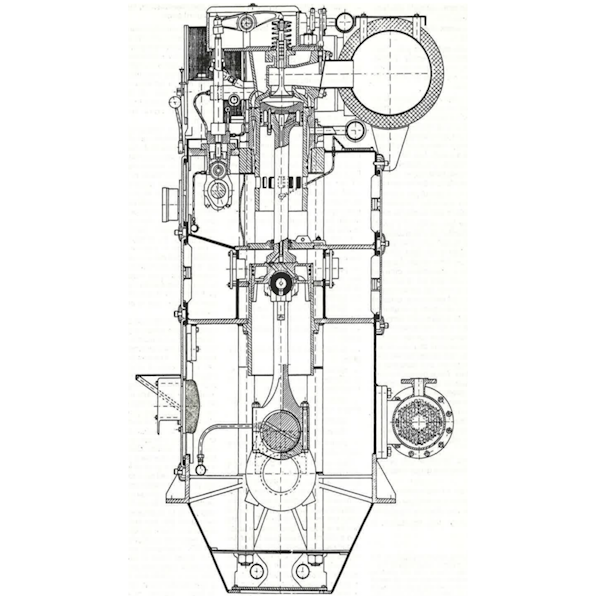

It is a 2-stroke, three-cylinder diesel engine, supercharged with turbocharger fed by exhaust gas, with a power of 221 kW (300 HP) and a speed of 500 rpm, with axial flow washing and overhead exhaust valve, cross head made piston, so as to also work as a scavenging pump.

Lubrication is separated in two circuits, as usual in large two-stroke diesel engines:

- a first circuit for the lubrication of the crank mechanism with higher quality and longer-lasting long/life "crankcase oil";

- a second circuit for the lubrication of the cylinder-piston, with "cylinder oil" capable of withstanding the high temperatures reached during combustion and the attack of combustion products.

The engine was used in the laboratory, after a modification: the cylinder oil circuit was divided into independent circuits, one for each of the three cylinders. This intervention allowed to examine different types of oil during the same test. In this way, it was possible to achieve the dual objective:

- saving time;

- reliability of the test results, which normally requires very accurate systems to reproduce tests in constant conditions.

One of the several publications relating to the engine (G. Landri, A. Paciolla, F. Quaranta, “Fuels and lubricants for marine diesel engines: problems, regulations, experiments”, La Termotecnica, 10, pp.69-82, 1989) reports that at the time, in Italy, the only example of Bolnes was the one installed at the Istituto Motori of Naples.

The experimental research had two objectives:

- to identify the operating characteristics of diesel engines with low quality fuels and lubricants (an ever present purpose, even currently);

- to stimulate the action from official organization to standardise procedures.